Understanding Engine Parts: How They Function Together for Optimal Performance in Your Vehicle

In the realm of automotive engineering, understanding the synergy between various components is essential for achieving peak performance. Renowned parts engine expert, Dr. Emily Carter, once stated, "Every part of an engine has a crucial role to play; it's the harmony between them that ensures the vehicle operates at its best." This highlights the importance of not only recognizing individual components but also understanding how they work together in unison.

The complexity of a vehicle's engine system can often seem daunting, yet a deeper comprehension of each part’s function can lead to better maintenance and performance. From the crankshaft to the camshaft, each part engine contributes to the overall efficacy of the vehicle. This article will delve into the top ten engine parts that are vital for optimal performance, shedding light on their roles and interactions. By exploring these components, both novice enthusiasts and seasoned mechanics can appreciate the intricate dance of power generation and efficiency that occurs within the engine bay. Whether you’re looking to enhance your vehicle’s performance or simply deepen your understanding of automotive mechanics, this journey through engine parts will be enlightening.

Key Components of an Engine and Their Roles in Vehicle Performance

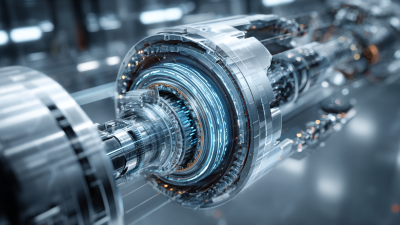

The internal combustion engine is a complex assembly of various components that work together to convert fuel into motion. Among the key components, the cylinder and piston play crucial roles. The cylinder serves as the chamber where the fuel-air mixture is ignited, producing an explosion that drives the piston downward. This action transforms chemical energy into mechanical energy, allowing the vehicle to move. The synchronization of the piston's movement with the crankshaft is essential for maintaining a smooth and efficient operation.

In addition to the cylinder and piston, the camshaft is another critical component that controls the timing of the engine's intake and exhaust valves. Proper timing ensures that air and fuel enter the combustion chamber, while exhaust gases exit efficiently. The role of the fuel injection system cannot be overlooked, as it accurately delivers the right amount of fuel to the combustion chamber, optimizing engine performance and reducing emissions. Together, these components exemplify the intricate design and engineering that enables vehicles to operate effectively and efficiently.

The Interconnection of Engine Parts: How They Work in Unison

Understanding how engine parts interconnect is crucial for maintaining optimal vehicle performance. Each component, from the pistons to the crankshaft, plays a specific role in the engine's operation. When these parts work in unison, they create the necessary power to propel your vehicle. For instance, the combustion process begins when air mixes with fuel and ignites in the cylinder, pushing the piston down and transforming energy into mechanical power. This seamless interaction illustrates how vital it is for each component to function correctly.

**Tips**: Regular maintenance checks can help detect any issues among these interconnected parts early before they escalate into major problems. Make sure to change your oil regularly, as it lubricates critical engine components, decreasing friction and wear. Additionally, keep an eye on your vehicle's temperature; overheating can lead to severe engine damage. Remember that small issues, if addressed promptly, can ensure your engine continues to perform at its best.

The timing of these components also plays a significant role in overall performance. For example, a malfunctioning timing belt can throw off the synchronization between the crankshaft and camshaft, leading to reduced efficiency and potential engine damage. Regularly inspect and replace your timing belt according to your vehicle manufacturer’s recommendations to maintain optimal performance.

Understanding the Functionality of Engine Valves and Timing Systems

In the intricate world of automotive engineering, engine valves and timing systems play pivotal roles in ensuring optimal vehicle performance. Engine valves control the intake of air and fuel while facilitating the exhaust of combustion gases. According to a report by the Society of Automotive Engineers (SAE), poorly functioning valves can lead to a decrease in engine efficiency by as much as 25%. This emphasizes the importance of regular maintenance and precise calibration to uphold performance standards.

The timing system, which includes components such as the camshaft and timing belt, synchronizes valve movements with the engine's piston movements. A well-timed engine allows for maximum airflow and fuel intake, which is crucial for achieving the desired power output while minimizing fuel consumption. Research indicates that a timing misalignment of just a few degrees can result in a loss of up to 10% in horsepower, showcasing the critical relationship between timing systems and overall engine functionality.

Therefore, understanding the dynamics between engine valves and timing systems is essential for maintaining vehicle performance and longevity.

The Impact of Fuel Injectors and Combustion Chambers on Efficiency

Fuel injectors and combustion chambers are pivotal components in achieving optimal engine performance and efficiency. Fuel injectors are responsible for delivering the precise amount of fuel into the combustion chamber at the right time, ensuring a fine mist that mixes well with air. This allows for a more complete combustion process, which is essential for maximizing power output while minimizing fuel consumption and emissions. Modern fuel injection systems are designed to adapt to various driving conditions, providing the right mix of air and fuel that enhances engine responsiveness and efficiency.

On the other hand, the combustion chamber plays a critical role in the combustion process itself. It is where air and fuel ignite, creating the pressure needed to drive the pistons and ultimately power the vehicle. The design of the combustion chamber affects how efficiently this process occurs; factors such as shape, volume, and surface texture influence turbulence and heat retention. A well-designed combustion chamber promotes an optimal air-fuel mixture and ensures that combustion occurs uniformly, reducing the likelihood of knocking and improving overall engine longevity. Together, these components define the efficiency and performance of modern vehicles, making their understanding essential for anyone looking to optimize their vehicle’s capabilities.

Understanding Engine Parts: How They Function Together for Optimal Performance in Your Vehicle - The Impact of Fuel Injectors and Combustion Chambers on Efficiency

| Component | Function | Impact on Efficiency | Key Characteristics |

|---|---|---|---|

| Fuel Injector | Delivers fuel to the combustion chamber | Essential for optimal air-fuel ratio, improving combustion efficiency | Precision, flow rate, spray pattern |

| Combustion Chamber | Houses the fuel-air mixture during combustion | Influences power output and fuel efficiency | Shape, volume, and material |

| Piston | Moves up and down to compress the air-fuel mixture | Affects engine power and efficiency during strokes | Material, size, and compression ratio |

| Intake Valve | Regulates the entry of air-fuel mixture into the chamber | Crucial for airflow, affecting performance and emissions | Timing, lift, and diameter |

| Exhaust Valve | Allows exhaust gases to exit the combustion chamber | Impacts back pressure, influencing performance | Timing, lift, and durability |

Maintaining Optimal Engine Performance Through Regular Maintenance Practices

Regular maintenance is crucial for keeping your vehicle's engine running at peak performance. According to a report from the Automotive Maintenance Association, neglecting regular engine maintenance can lead to a decrease in fuel economy by as much as 10%. Simple tasks like changing the oil, replacing air filters, and checking spark plugs can significantly enhance engine efficiency. By following a structured maintenance schedule, drivers can not only prolong the lifespan of their engines but also save on fuel costs.

One effective tip for maintaining optimal engine performance is to adhere to the manufacturer's recommended service intervals. For example, the American Automobile Association (AAA) suggests that an oil change should typically occur every 5,000 to 7,500 miles, depending on the vehicle's make and model. Additionally, regularly inspecting coolant levels and ensuring that belts and hoses are in good condition can prevent unexpected breakdowns.

Lastly, consider investing in high-quality engine components. A study published by the International Journal of Engine Research indicated that using OEM (Original Equipment Manufacturer) parts could lead to a 25% improvement in engine reliability compared to generic alternatives. Prioritizing maintenance and quality components not only enhances performance but also ensures that your vehicle remains safe and enjoyable to drive.

Related Posts

-

Unlocking the Future: How Emerging Technologies are Revolutionizing the Motor Parts Industry

-

Top Trends in Car Bearings for Enhanced Vehicle Performance

-

Understanding the Role of Car Distributors: Your Guide to a Smooth Automotive Supply Chain

-

Understanding the Importance of Engine Bearings for Enhanced Vehicle Performance

-

The Hidden Role of Car Bearings in Ensuring Smooth and Safe Driving

-

Exploring Key Car Factors: How They Influence Your Vehicle’s Performance and Value