Understanding the Importance of Engine Bearings for Enhanced Vehicle Performance

Engine bearings are critical components in the intricate machinery of a vehicle, playing a pivotal role in enhancing overall performance and longevity. Understanding the importance of engine bearings involves delving into their functions, types, and the materials used in their construction, which collectively contribute to the efficiency of an engine. These small yet essential elements are responsible for reducing friction between moving parts, supporting the crankshaft, and maintaining proper alignment. Without high-quality engine bearings, vehicles may experience increased wear and tear, leading to costly repairs and diminished performance.

In this guide, we will explore the various aspects of engine bearings, including how to choose the right type for your vehicle, the signs of wear to watch for, and tips for maintaining them to ensure optimal performance. By gaining insight into these components, vehicle owners can make informed decisions that impact not just their engine's health but also their overall driving experience.

How Engine Bearings Impact Overall Vehicle Performance

Engine bearings play a crucial role in the overall performance of a vehicle, acting as the vital connection between engine components. By reducing friction between the moving parts, these bearings help maintain optimal engine temperature and efficiency, thereby enhancing power output and fuel economy. Recent advancements in engine technology, such as turbocharging, further emphasize the importance of quality engine bearings in maximizing performance. Utilizing robust bearings can lead to better performance metrics and longevity of the engine, ensuring that drivers experience smooth and powerful rides.

**Tips:** When maintaining your vehicle, consider the condition of your engine bearings. Regular inspections can prevent excessive wear and tear that may adversely affect vehicle performance. Additionally, when upgrading to high-performance parts, ensure that the bearings are compatible with these modifications to maximize benefits.

Furthermore, as the automotive industry evolves with innovations like E20 fuel and timing chain technologies, the importance of compatible engine components, including bearings, cannot be overstated. Use of such fuels in engines without appropriate specifications can lead to inefficiencies and potential damage. Thus, understanding the interplay between engine bearings and fuel types can empower vehicle owners to make informed decisions for maintaining peak performance.

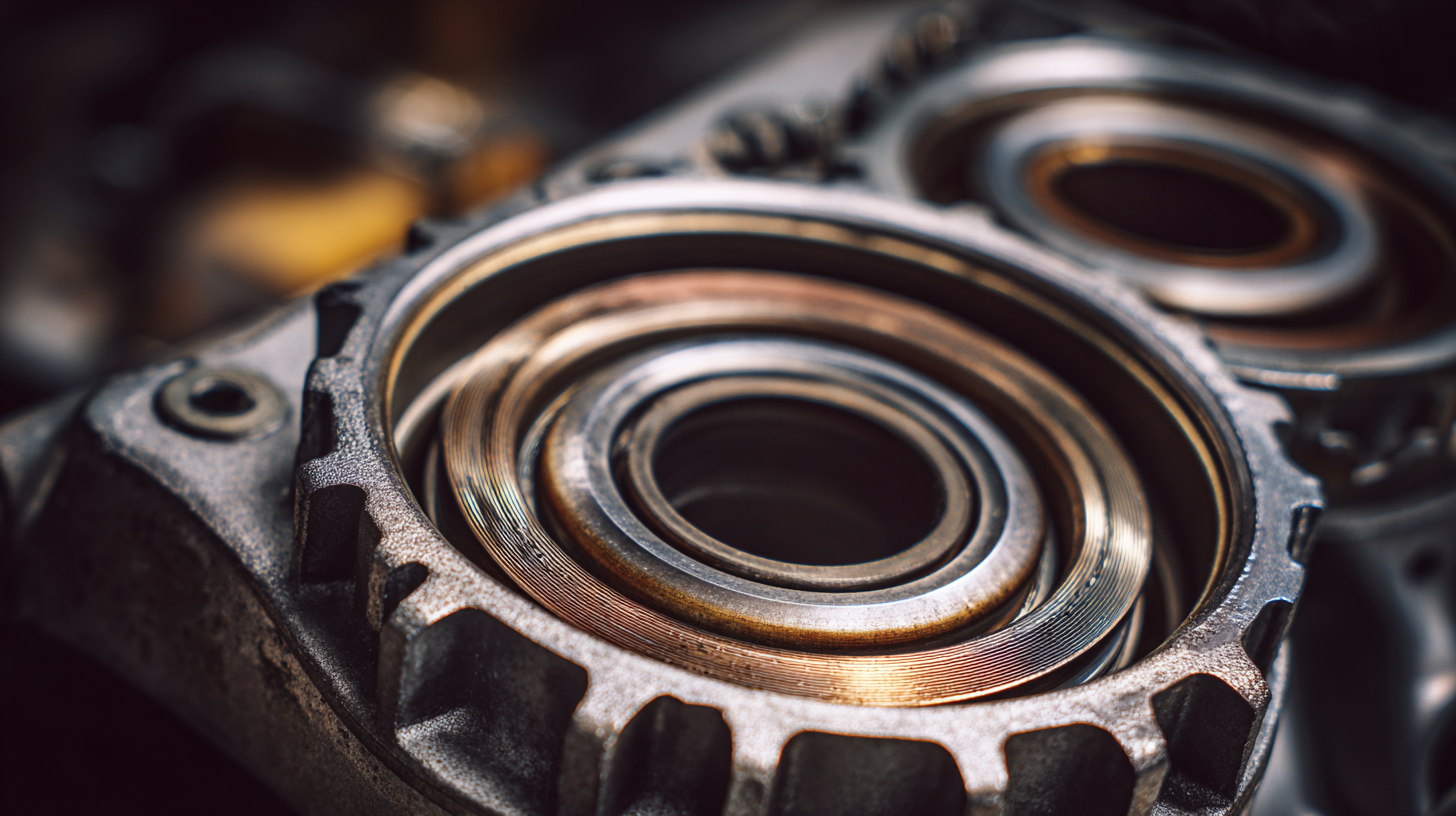

Understanding Different Types of Engine Bearings and Their Functions

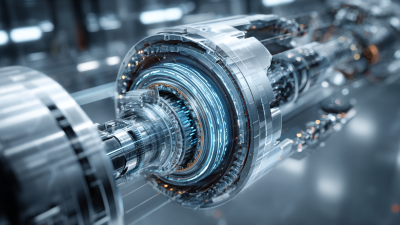

Engine bearings are critical components in automotive engines, playing a crucial role in the overall functionality and performance of vehicles. There are several types of engine bearings, each serving specific purposes. The most common types include main bearings, connecting rod bearings, and thrust bearings. Main bearings support the crankshaft, allowing it to rotate smoothly while handling the engine's load, while connecting rod bearings provide the necessary support for the connecting rods, enabling efficient transfer of motion from the pistons to the crankshaft.

Thrust bearings, on the other hand, help manage the axial movement of the crankshaft, preventing excessive play that could lead to failure. Each type of bearing is designed to accommodate varying loads and operating conditions, utilizing materials that reduce friction and wear. It's essential to select the appropriate type of bearing for an engine to ensure optimized performance, longevity, and reliability. By understanding the functions and characteristics of different engine bearings, vehicle owners and mechanics can make informed decisions to enhance engine performance and overall vehicle efficiency.

Understanding the Importance of Engine Bearings for Enhanced Vehicle Performance

| Type of Engine Bearing | Function | Material Used | Key Features |

|---|---|---|---|

| Main Bearings | Supports the crankshaft and transfers loads | Steel, aluminum | High durability, excellent load capacity |

| Rod Bearings | Connects the piston to the crankshaft | Bronze, lead-based | Resistant to wear, heat dissipation |

| Camshaft Bearings | Supports the camshaft rotation | Cast iron, aluminum | Precision alignment, reduced friction |

| Thrust Bearings | Prevents axial movement of the crankshaft | Copper, steel | Control side loads, longevity |

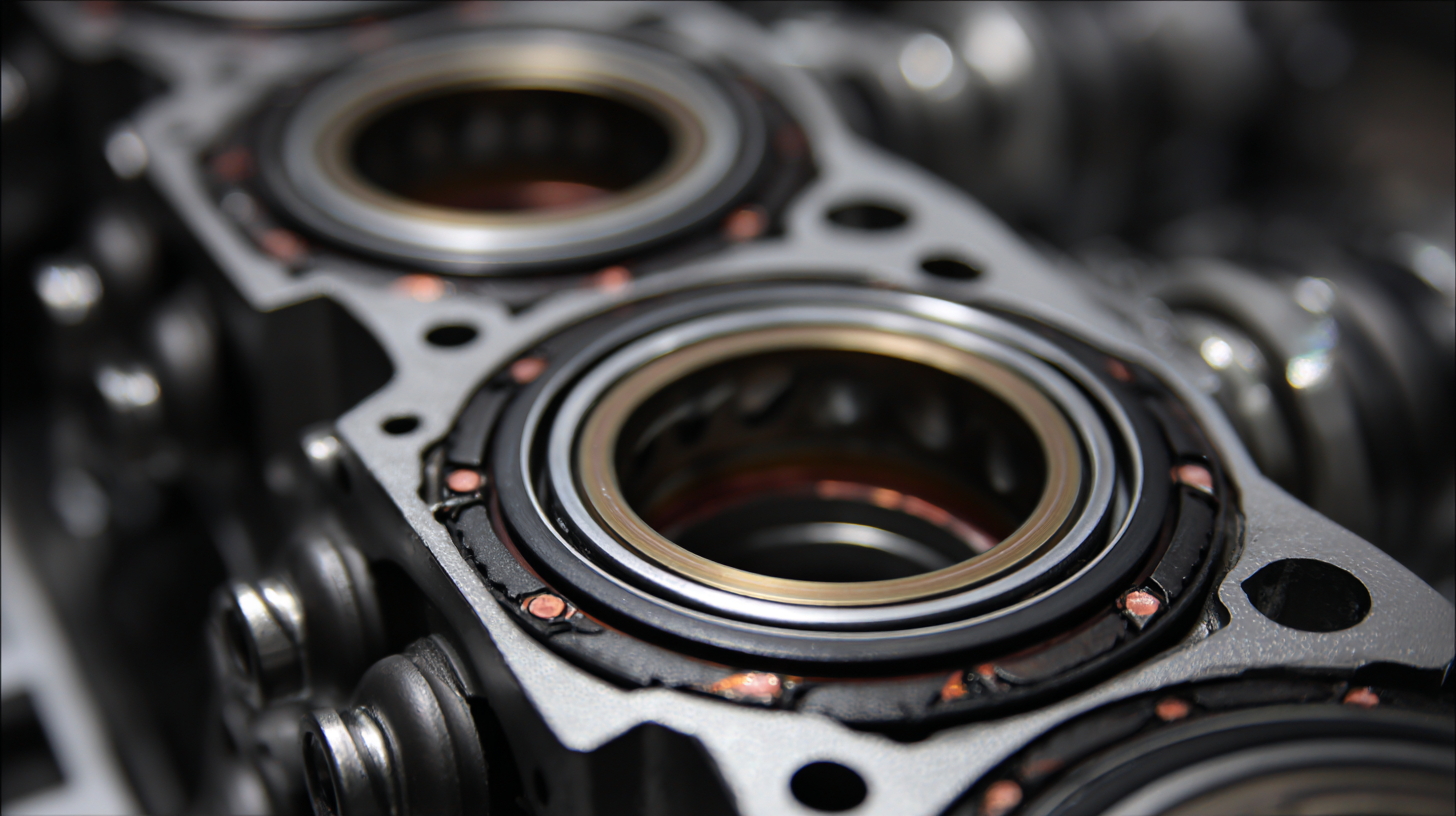

Signs of Worn Engine Bearings and How to Identify Them

Worn engine bearings can significantly impact vehicle performance, leading to increased friction, noise, and potential engine failure. One key sign of worn engine bearings is a noticeable knocking sound, particularly during acceleration or when the engine is under load. According to a report by the Society of Automotive Engineers (SAE), around 30% of engine failures are attributed to bearing wear, highlighting the critical nature of this component in maintaining engine health.

Another indicator of deteriorating bearings is the presence of metal shavings in the oil filter or oil pan. Frequent oil changes often alleviate some wear but may not resolve the underlying issue of damaged bearings. The American Petroleum Institute (API) suggests that regular oil analysis can help detect anomalies such as metal wear particles, enabling early intervention. Additionally, if a driver's vehicle exhibits inconsistent oil pressure readings, it could signal bearing issues, necessitating immediate diagnostic checks to prevent severe engine damage. By recognizing these signs early, vehicle owners can ensure better performance and longevity of their engines.

Signs of Worn Engine Bearings and Their Impact on Vehicle Performance

Best Practices for Maintaining and Replacing Engine Bearings

Engine bearings play a critical role in ensuring the smooth operation of a vehicle's engine, and maintaining them is essential for enhanced performance. Regular checks and timely replacement of worn-out bearings can prevent significant engine damage and improve overall vehicle efficiency. To achieve optimal performance, drivers should adopt best practices for maintaining and replacing engine bearings, which generally involve regular inspections and adherence to manufacturer recommendations.

Tips for maintaining engine bearings include regularly changing the oil and oil filter, as clean oil is vital for reducing friction and wear on the bearings. Additionally, ensuring that the engine is properly tuned can help mitigate stress on component parts. When it comes to replacement, always opt for high-quality bearings that meet the vehicle’s specifications to guarantee longevity and performance. Engaging in scheduled maintenance checks can help identify issues before they escalate, ultimately saving time and reducing repair costs.

Furthermore, it's important to pay attention to abnormal engine noises or vibrations, as these could indicate bearing failure. Promptly addressing any such issues can lead to significant savings in costly repairs down the line. By implementing these best practices, vehicle owners can ensure their engines operate at peak performance, thereby enhancing both reliability and driving enjoyment.

Upgrading Engine Bearings for Enhanced Performance and Longevity

Upgrading engine bearings is a critical step in enhancing both the performance and longevity of a vehicle. Engine bearings play a vital role in reducing friction between moving parts, which is essential for efficient operation. When upgrading to high-performance bearings, drivers can experience significant improvements in engine responsiveness and power output.

High-quality bearings enable smoother movement and reduce heat generation, allowing the engine to perform optimally, even under demanding conditions.

Additionally, the longevity of an engine is directly influenced by the type of bearings used. Standard bearings may wear down more quickly under high stress, leading to potential engine failure and costly repairs. By investing in upgraded bearings made from advanced materials, vehicle owners can minimize wear and tear, resulting in extended engine life.

This proactive approach not only enhances immediate performance but also ensures a more reliable and durable engine over time, making it a worthwhile investment for any automotive enthusiast or driver seeking to enhance their vehicle's capabilities.

Related Posts

-

Unlocking the Future: How Emerging Technologies are Revolutionizing the Motor Parts Industry

-

The Hidden Role of Car Bearings in Ensuring Smooth and Safe Driving

-

Understanding the Role of Car Distributors: Your Guide to a Smooth Automotive Supply Chain

-

Ultimate Guide to Choosing the Best Brake Parts for Your Vehicle

-

Exploring Key Car Factors: How They Influence Your Vehicle’s Performance and Value

-

Discover the Essential Car Pieces Every Vehicle Owner Should Know About